SAP SD Material Master Data and Master Data Management is of core importance in SAP. A transaction’s accuracy is based on correct and accurate Master Data. If the Master Data is not maintained in the SAP system, transactions cannot be performed. If the Master Data is not properly and accurate maintained, process like either Procure-to-Pay or Order-to-Cash, Record-to-Report, Hire-to-Retire, Plan-to-Produce will not be processed accurately. If same are not processed accurately, accurate reporting cannot be obtained by any means.

The importance of Master Data can be understood by this example that many companies have experienced and dedicated Master Data Management resources in their Master Data Management team meaning, there are set of employees who are dedicated and solely look after Master Data they are usually called the Master Data Management (MDM) team. They carefully consider the Master Data, responsible for entering accurate data in prescribed fields. They also closely observe, look vigilantly and check thoroughly if there’s any repetition, duplication and redundancy of the Master Data.

Material master in SAP is used by different modules. Here you can find tutorials about using SAP material master in other modules:

Introduction to SAP SD Material Master

SAP SD Material Master is a centrally shared data used by all logistics modules. Information captured in the Material Master record can be descriptive or can have functional control depending on the usage. This information can be maintained across several organization levels or can be maintained for specific organization level (e.g., plant, storage location, sales organization, etc.)

SAP SD Material Master Data in SAP has several material types. Each material type has its own set of ‘Views’. By ‘Views’ in SAP Material Master data we mean areas (tabs) and their fields which are required to be filled up or populated for smooth processing of transaction and processes.

Material Master in SAP is used by following modules:

- Material Master

- Production Planning

- Quality Management

- Plant Maintenance

- Finance

- Controlling

- Warehouse Management

Each view has its own functionality, and their fields have their own meaning. If any of the view is not maintained, the respective module cannot perform their activity. E.g., to make a material salable, Sales and Distribution Views must be maintained. Similarly, to carry out quality check on the received material, Quality Management View in SAP material must be maintained with accurate settings.

Material Types

The Material Type groups materials with similar characteristics and attributes. It also determines whether the material will be valued at a standard price or at a moving average price. It also maintains which screens are to be maintained depending upon the screen sequence assigned. Once a material has been maintained in the SAP system and if any change is needed, the Material Master record can either be:

- Extended: SAP SD Material Master extension is done when organizational level data or departmental data has not been maintained. The extension process allows the user to define these levels (e.g., the purchasing data view has not been maintained or the material has not been extended for a certain storage location)

- Changed: If the data maintained needs to be altered, the record can be changed using the material master change transaction

SAP Material Master Data for Sales & Distribution

Sales processing is based on the following basic structures:

- In Sales and Distribution, products are sold to Customers and / or services are performed for them. Related Master Data about the products and services are maintained in the SAP SD Material Master Data. Sales processing with the SAP System require that the master data has been stored in the system.

- The processing of business transactions in Sales and Distribution is based on the Master Data. In the SAP System, business transactions are stored in the form of documents. These Sales and Distribution documents are structured in such a way that all necessary information in the document is stored in a systematic way.

A Material Master record is either created or extended when:

- No Material Master Data record exists for the material in the first place.

- Material master record exists for the material but has not been created for a certain organizational level, e.g. Plant, Sales Organization or Storage Location.

When an end user in the Sales department needs to sell a material, this user will search for the Material in the SAP. If the material is not available, the user will raise a request with the concerned department or a person responsible for Master Data creation/maintenance, so that the material master record is created in the system. The department/ person responsible for creating SAP Material Master will create Master Data by selecting correct material type and entering all the relevant information.

Master data relevant to materials is more specifically pertaining to the Materials Management (MM) module’s domain. However, each salable material is extended to a combination of Sales Organization and Distribution Channel (sales line), for carrying out sales.

Unless a material is not extended to at least one sales line, the system will not allow the user to record sales in the SAP. Material Master can be extended to multiple combinations of Sales Organizations and Distribution Channels (sales lines) by maintaining sales related views.

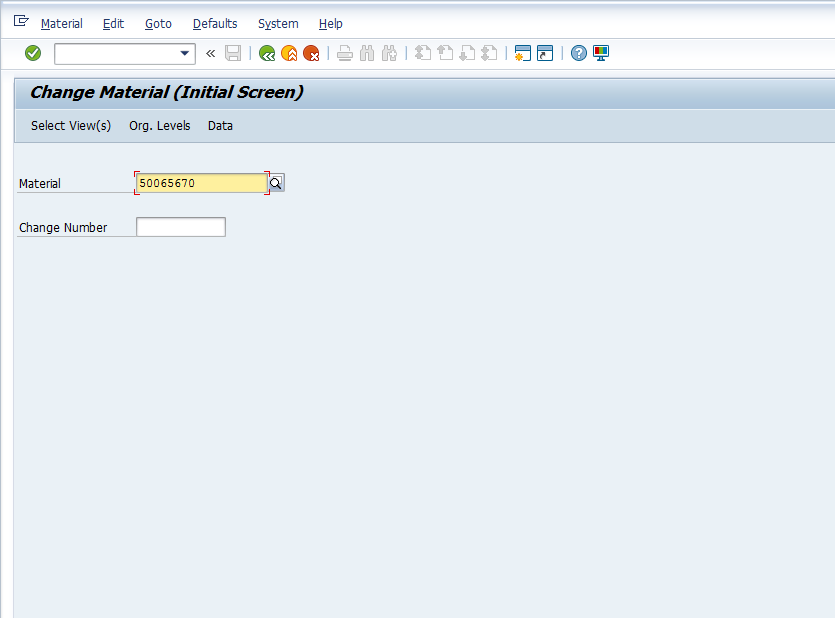

The following ‘Sales Views’ are relevant for all salable materials:

- Sales: Sales Org. Data 1:

- Basic sales relevant data, tax classifications, delivering plant, units of measure (e.g., base & sales unit of measure)

- Sales: Sales Org. Data 2:

- Account Assignment Group of Material, Material groupings (e.g., product hierarchy, material group)

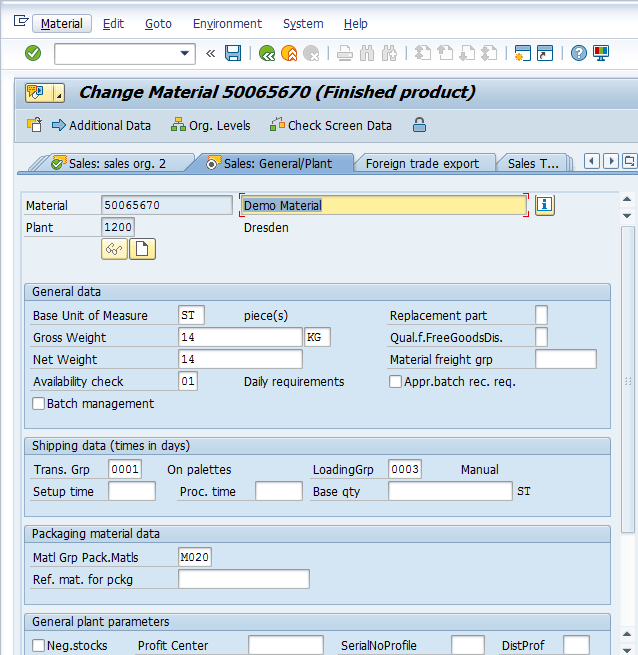

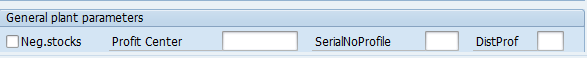

- Sales: General/Plant Data:

- Sales and Shipping data (e.g., gross and net weight, availability check strategy, transportation group, loading group), profit center can also be entered here

Important SAP SD Material Master Transactions

Following are the key transaction related to SAP SD Material Master:

- MM01 – Create Material Master

- MM02 – Change Material Master

- MM03 – Display Material Master

- MM06 – Flag for Deletion

- MM60 – Material Master List

How to Create SAP SD Material Master

There are two options to start the transaction for creating a new material.

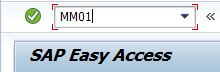

- Enter MM01 in Transaction Command Field or executing Material Master – Creation Transaction / Screen

- Navigate through ‘Tree’

SAP SD Material Master Data – Sales & Distribution ‘Views’

As a responsible for SAP SD module, chances are likely that Material Master’s basic information will be maintained by a person from SAP MM team and the material number will be generated. You will be responsible for maintaining SAP Sales & Distribution relevant data in the Master Master’s Sales Views.

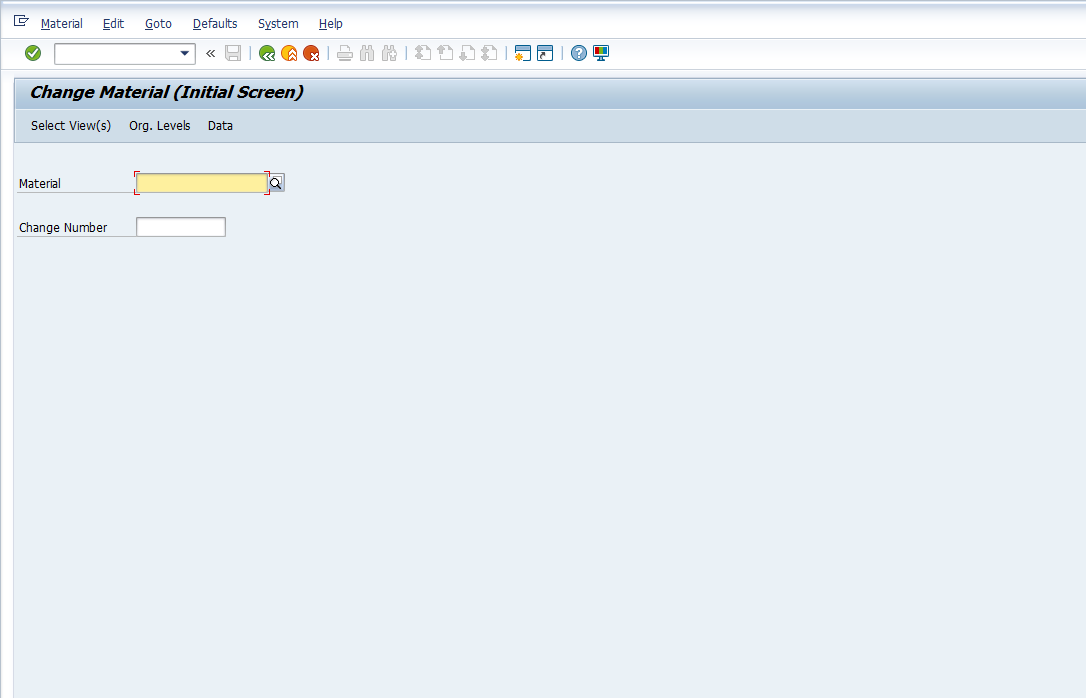

Let’s look at SAP’s Material Master Data Views related to Sales & Distribution Module. In the main screen of Material Master transaction (MM01), enter the material you wish to maintain SD’s views and press Enter.

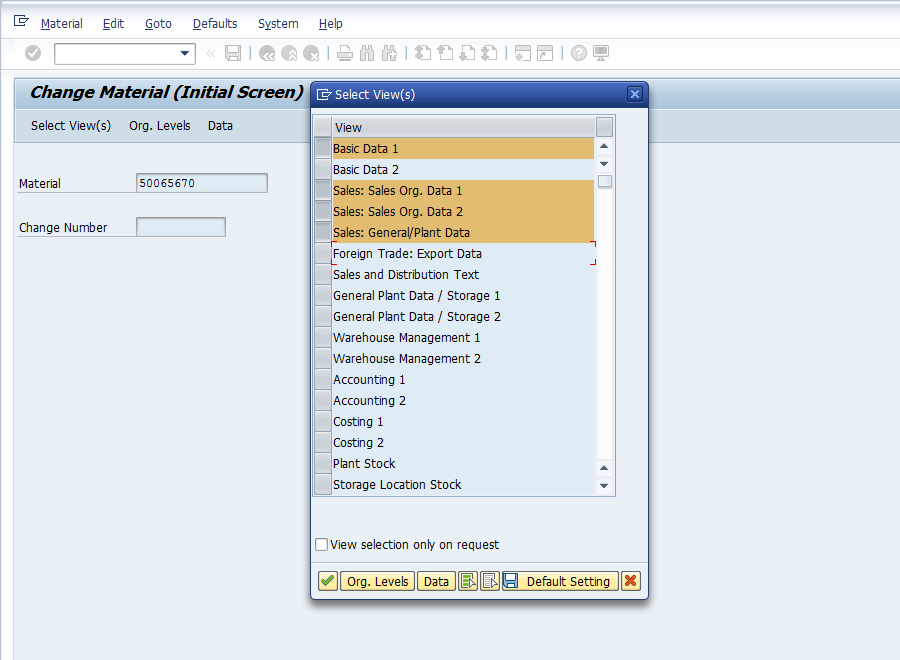

Once you press Enter a dialog box will appear to select the views you wish to maintain, change or display.

In this case, we will select Basic Data 1 and SD’s Views and press Enter.

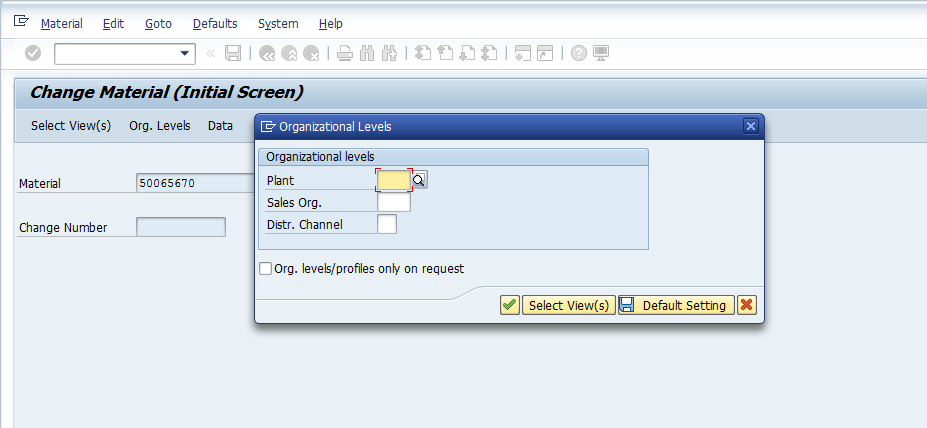

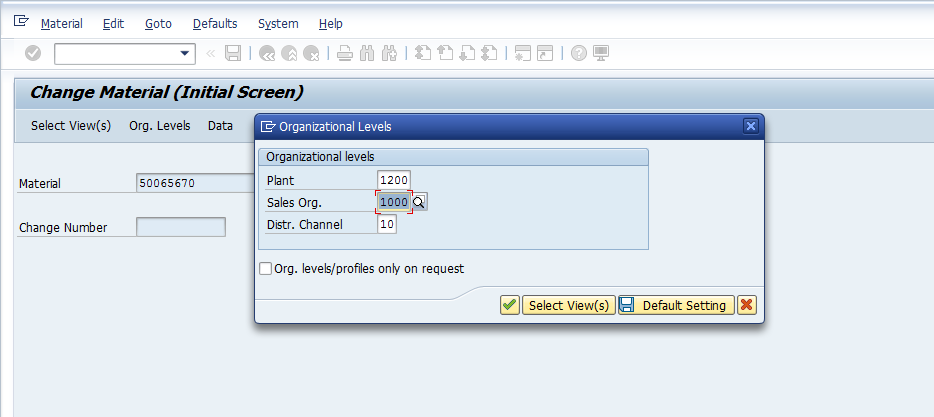

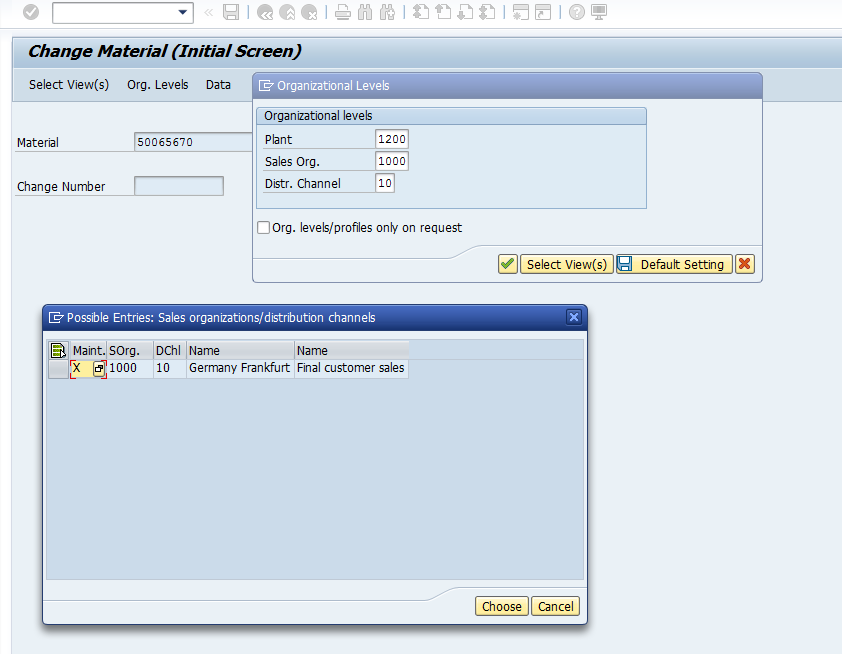

Once you press Enter, another dialog box will appear. Enter relevant Plant, Sales Organization and Distribution Channel for which you wish to maintain, change and display SD’s Material Master values and press Enter.

Hint: In Change and Display transactions, if you either press F4 or ![]() button and SAP system will display all values of Plant, Sales Organization and Distribution Channel where the selected material is already maintained.

button and SAP system will display all values of Plant, Sales Organization and Distribution Channel where the selected material is already maintained.

Once you press Enter, you will reach the view which you have selected.

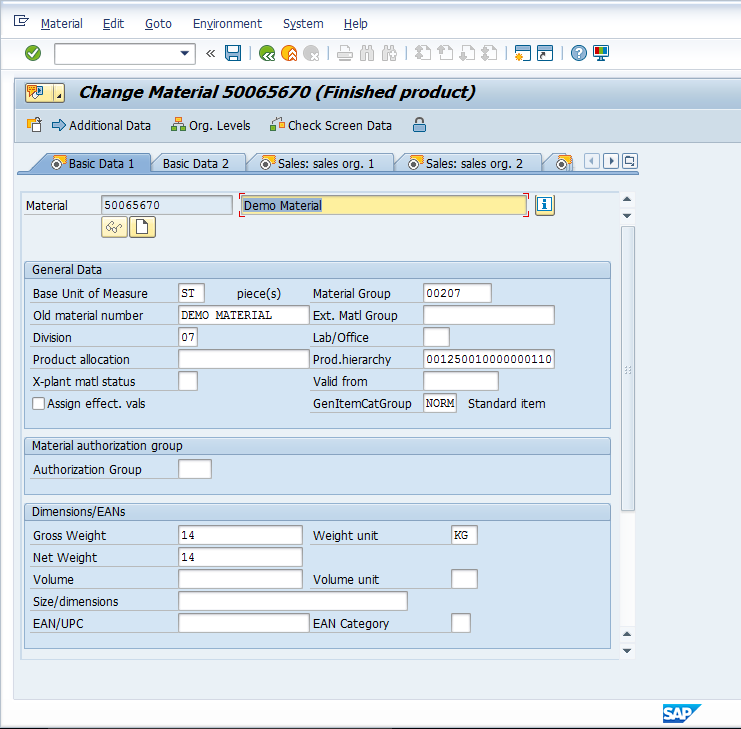

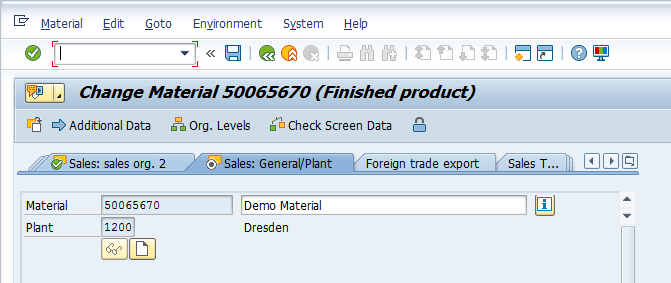

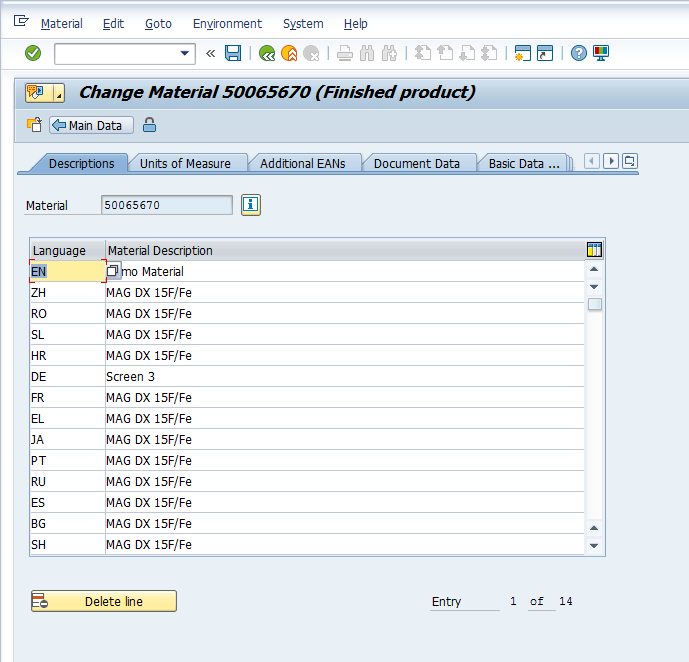

In the Basic Data tab, as the name suggests, it contains information basic information about the product. Product’s description, Base Unit of Measure / stock keeping unit, Material Group to which it belongs, old material number, Division, Weight, Volume, Dimensions, etc. When you press Enter, after maintaining, changing or viewing the data in the tab, the system will take you to the next tab which you have selected in the previous screen.

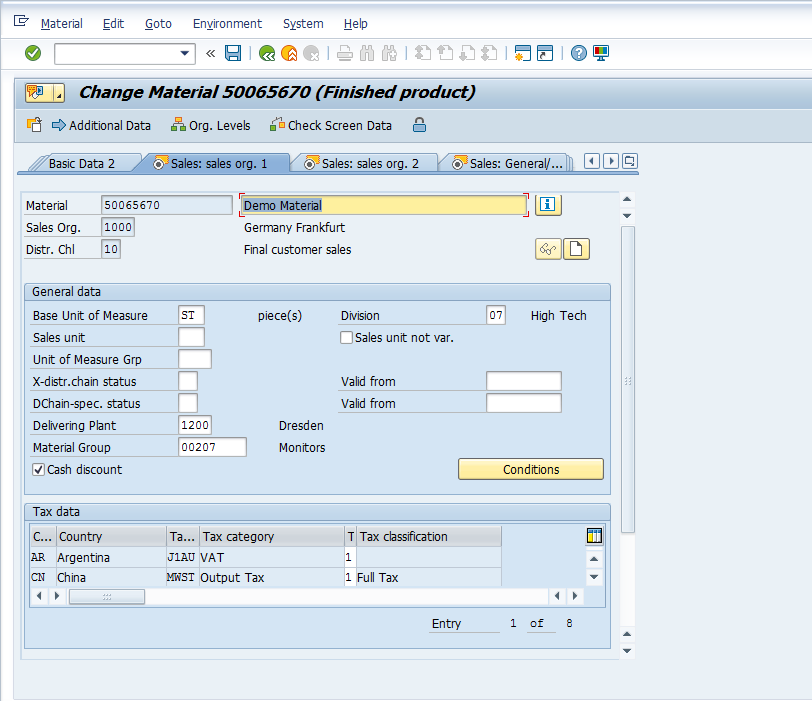

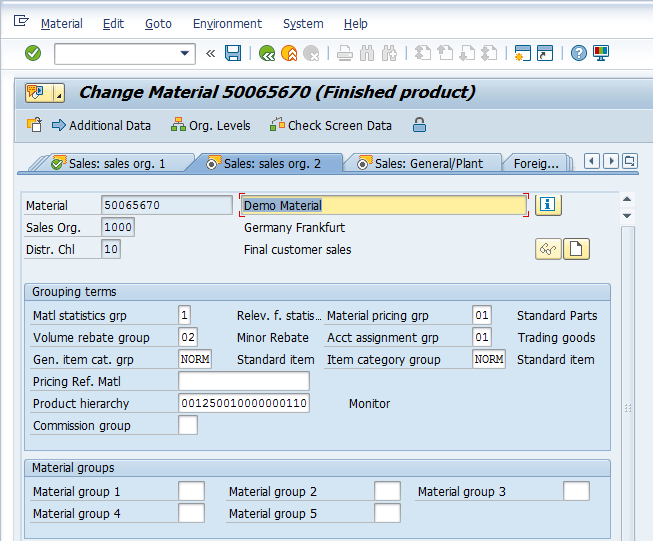

On the screenshot above is the Sales: sales org. 1 screen. The header part contains the information which you have selected initially.

Below is the General data part:

It contains basic information like the Base Unit of Measure which have been selected by the warehouse as the lowest stock keeping unit.

Sales Unit which can be same or different to Base unit of measure. Example: warehouse stocks a material in Pieces whereas the Sales is carried out in boxes or cartons. For this, an alternate unit of measure shall be maintained which we will have a look at the later part of this tutorial.

Unit of Measure Group is the option that you can use for grouping several units of measure.

Division – the product line or group of materials to which this material belongs.

Delivering Plant – the plant from where the said material is shipped to a customer.

Material Group – option to group materials and services due to their distinct nature.

Conditions – takes you to the pricing master where you can maintain the base price of the selected material.

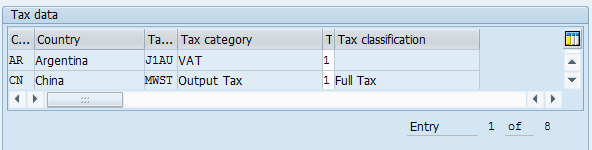

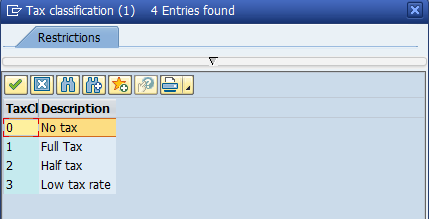

Tax Data contains the taxation details for the material country wise. A material can either be non-taxed material, half tax, full tax or exempted.

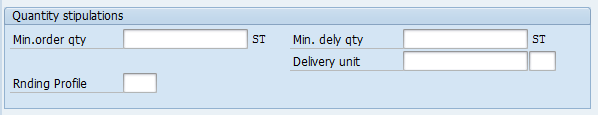

Quantity stipulations contain information regarding the minimum order and delivery quantity that the customer should order so that goods can be shipped.

Delivery Unit – specific multiples in which goods can be shipping.

After you are done with Sales: sales org. 1 view, press Enter and the system will take you to the second view Sales: sales org. 2 provided that you have selected the said view on the initial views selection dialog box.

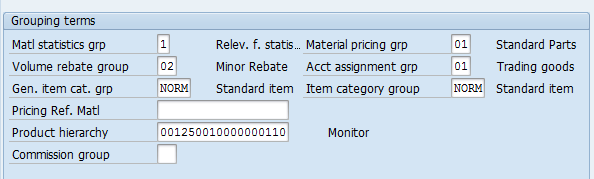

Grouping terms allows to group the material on certain criteria

Material statistics grp – is required for SIS (LIS) reporting.

Material pricing grp – is used for pricing condition purposes. Example, if you want to have a certain set of materials with the same base price or discounts, etc.

Volume rebate group – group used for rebate settlement.

Account assignment grp – used for account determination and selection relevant G/L at the time of posting Sales invoice.

Gen. item cat. grp – grouping materials to define item categories and selection of relevant item categories during sales order processing.

Item category group – used for selection of relevant item category in the Sales Order automatically.

Pricing Ref. Matl – master record that the system uses as a reference for pricing purposes.

Product Hierarchy – for grouping together materials by combining different characteristics. It is used for analyses and price determination.

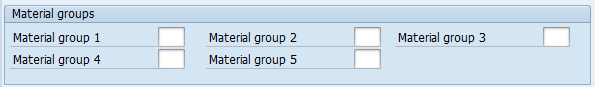

Material Groups are used to classify the material based on its different attributes, e.g. size, packaging, color, etc. for analysis purposes.

Once you are done with Sales: sales org. 2 view, press Enter and the system will take you to the third view Sales: General/Plant view provided that you have selected the said view on the initial views selection dialog box.

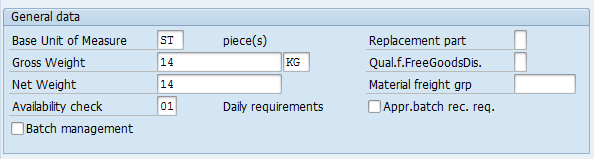

Base Unit of Measure, Gross and Net Weight – will be copied from the Basic Data screen, if they were populated there.

Availability Check – check group which defines whether and how the system checks the material’s availability and generates requirements for materials planning.

Batch Management – if the material is managed, stored and shipped in batches.

Material freight grp – is used to group materials so that they can be classified according the shipping and freight requirements.

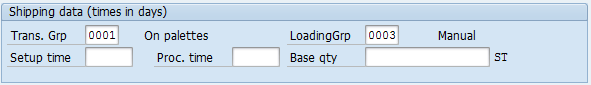

Shipping data contains information which is relevant for shipping and should be maintained in the material master for smooth shipping activities at the Distribution Center.

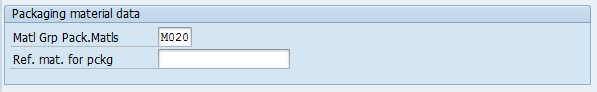

Packaging Material Data contains information if this material requires packaging and what type of packaging at the time of shipment / dispatch.

General Plant Parameters contain information if the negative of the material is all allowed. Profit Center to which this material belongs to. It is important for Profit Center Accounting in Controlling.

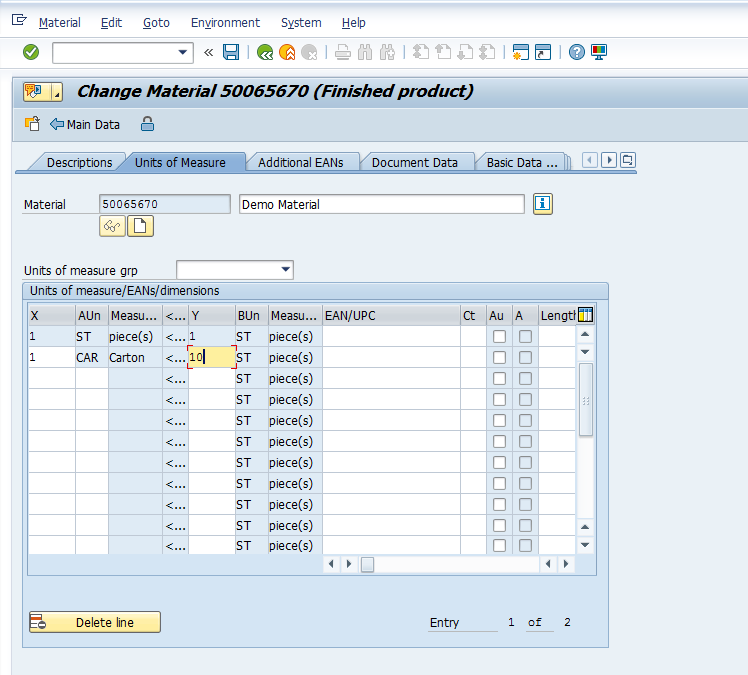

Additional Data – Alternate Units of Measure

As discussed briefly above, if your stock keeping unit at warehouse is different than your sales unit, the conversion of the same can be maintained in the Alternate Units of Measure. It contains, for example, ‘X’ number of Base Unit of Measure contains ‘Y’ number of Sales Unit.

To reach to the Additional Data view, select ![]() button.

button.

Select ![]() tab to enter conversion.

tab to enter conversion.

Here in this example, it is shown that 01 Carton, which is a Sales Unit, contains 10 ST pieces of Base Unit of Measure. Once you are done with maintaining and changing values in the SAP Sales & Distribution ‘Views’ of SAP SD Material Master, don’t forget to Press Save ![]() or CTRL+S for the values to take effect in your sales transactions.

or CTRL+S for the values to take effect in your sales transactions.

Did you find this tutorial helpful? If you have any questions or comments, we would appreciate your feedback in the comments section below. Your input would be greatly beneficial to us, and it may be something we can incorporate to enhance our free SAP SD tutorials.